It is these assumptions that are causing problems. To calculate a cricondentherm the pipeline operator must make some assumptions. The C6+ component does not provide any information on the heavier hydrocarbon (C7+) components that determine the gas hydrocarbon dew point. However, many gas-transporting companies tend to collect gas composition data using on-line chromatographs or composite samples with a grouped C6+ component.

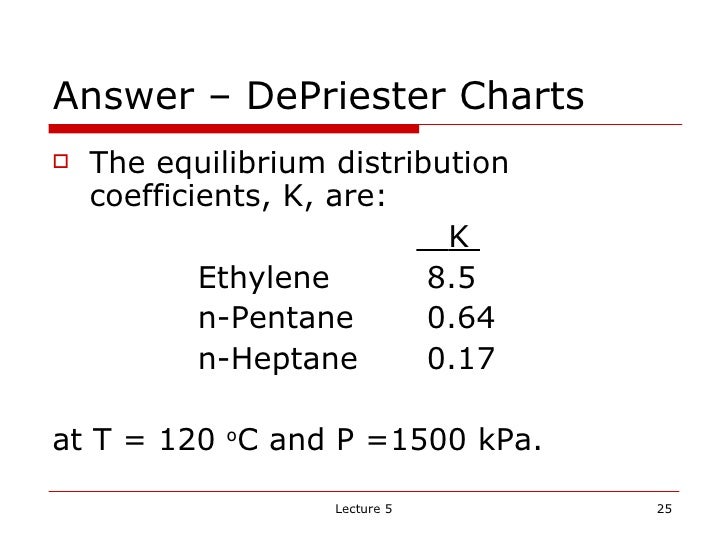

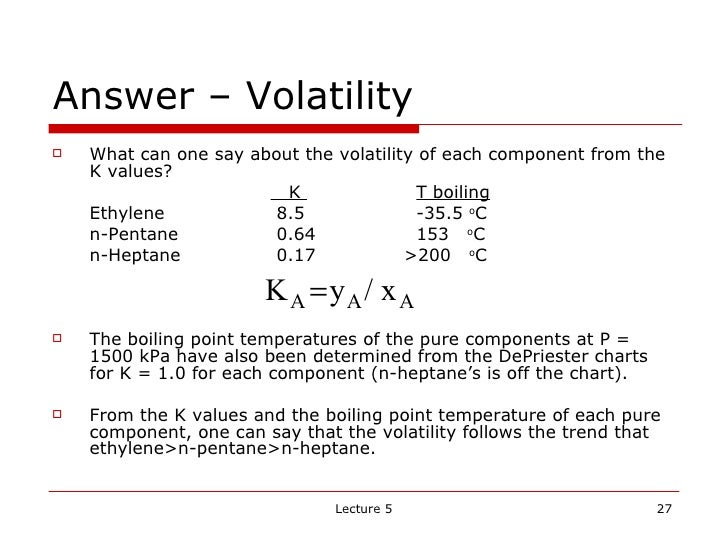

DEPRIESTER CHART FOR HYDROCARBONS TO FIND DEW TEMP SOFTWARE

The cricondentherm temperature is calculated by obtaining an extended gas analysis and then inputting the analysis data into a software package, using equations of state to predict the dew point temperatures at the range of pressures. The problem a pipeline operator has in using a cricondentherm specification is in the calculation of the cricondentherm temperature. Controlling dew point is also necessary to qualify the pipeline to market gas to high efficiency gas turbine end users that require a dry and consistent quality fuel.

citygates) that feed end user supply systems. Proper managing of gas dew point can also prevent liquids from forming as the gas cools while flowing through pressure reduction stations (e.g.

Also, removing pipeline liquids helps prevent pipe corrosion in the low areas where water is trapped under the hydrocarbon liquid layer and slowly destroys the pipe integrity. Most importantly, liquids in burners and pilots onsite and at end user locations at LDCs, can cause fire and explosion hazards. By managing hydrocarbon dew point, hydrocarbon condensation can be prevented in cold spots under rivers and lakes where the liquids collect in the low areas and then often move as a slug through the system, over pressuring the pipe, and overpowering liquid handling facilities, flowing into compressors and end user sales points. The gas transportation companies have come to the realization that managing hydrocarbon dew point reduces system liabilities, opens up new gas markets and generates operating revenue. At the sales meter, (without a conditioning unit) the hydrocarbon dew point is usually close to the lowest temperature the gas has achieved on the location before it was sampled, at operating pressure. The TEG dehydration unit will remove some heavy hydrocarbons, in addition to water, and further reduce the hydrocarbon dew point. As the gas leaves the separator and cools flowing through the piping system, liquids condense and the dew point decreases as the heavy ends condense. In other words, the gas leaving the separator is at its hydrocarbon dew point that equals the separator operating temperature (and pressure.) If the separator is operating at 100☏, then the gas has a 100☏ dew point at separator pressure. Therefore, the gas leaving the separator is in equilibrium with the oil.

In return, we ask the producer at what temperature does his high-pressure production separator operate? By definition, a production separator separating oil from gas operates at vapor-liquid equilibrium. “How can my hydrocarbon dew point be so high?” One of the first questions we are asked by producers with a hydrocarbon dew point issue is: The dew point temperature also moves in relation to pressure. It is the heaviest weight components that first condense and define the hydrocarbon dew point temperature of the gas.

Natural gas typically contains many liquid hydrocarbon components with the heavier components found in smaller amounts than the lighter gaseous ends. Hydrocarbon dew point (HDP) is similar to the water dew point issue, except that we have a multi-component system. It is easily removed using conventional techniques, primarily TEG (Triethylene Glycol) dehydration units. Water dew point is relatively simple and easy to predict since it is a single component system. The cold glass lowers the air temperature below the water dew point temperature and the water condenses on the sides of the cold glass. We also see it demonstrated by a cold glass “sweating” on a humid day. Air is cooled to its water dew point and the water starts condensing and collects into small droplets. Dew point is defined as the temperature at which vapor begins to condense.

0 kommentar(er)

0 kommentar(er)